SCADA stands for supervisory control and data acquisition. It generally refers to an industrial control system or a computer system, monitoring and controlling a process.

Industrial processes include those of manufacturing, production, power generation, fabrication, and refining. And may run in continuous, batch, repetitive, or discrete modes.

Infrastructure process includes water treatment and distribution, wastewater collection and treatment, oil and gas piplines, electrical power transmission and distribution, civil defense siren systems, and large communication systems.

Facility process includes buildings, airports, ships and space stations. They monitor and control HVAC, access and energy consumption.

Remote Terminal Unit (RTU)

The RTU connects to physical equipment. Typically, an RTU converts the electrical signals from the equipment to digital values such as the open/closed status from a switch or valve, or measurements such as pressure, flow, voltage or current. By converting and sending these electrical signals out to equipment the RTU can control equipment, such as opening or closing a switch or a valve or setting the speed of a pump. The RTU can range from compact PLC to large modular PLC or DCS.

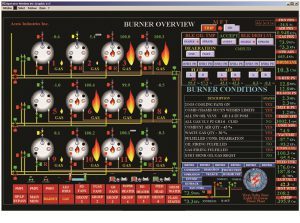

Human-machine Interface ( HMI)

A human-machine interface or HMI is the apparatus which presents process data to a human operator, and through which the human operator controls the process. An HMI is usually linked  to the SCADA system’s databases and software programs, to provide trending, diagnostic data, and management information such as scheduled maintenance, procedures, logistic information, detailed schematics for a particular sensor or machine, and expert system troubleshooting guides.

to the SCADA system’s databases and software programs, to provide trending, diagnostic data, and management information such as scheduled maintenance, procedures, logistic information, detailed schematics for a particular sensor or machine, and expert system troubleshooting guides.

The HMI system usually presents the information to the operating personnel graphically, in the form of a mimic diagram. This means that the operator can see a schematic representation of the plant being controlled.